Linear, Progressive, Regressive, Digressive Shock Valving: Differences and Use-Cases

June 27, 2022

Which is better: Running shoes or hiking boots? We both know that’s a silly question that’s impossible to answer without knowing one vital piece of information: The use case.

Shock valving styles are the same way.

The best style of damping curve for you will depend on your driving style, racing surface, and more. There are things you should avoid when setting up your racing suspension for dirt and different challenges you’ll encounter when setting up for pavement. As a result of these diverse needs from different drivers and situations, shock valving styles have evolved a great deal over the years.

We will cover some of the more common examples and some of the more revolutionary models. We’ll also shed some light on where all these different shock builds have come from, where they are currently being used, and maybe how they might be able to help you master the process of suspension tuning.

Valve Stacks and Shock Absorbers: Parts and Interactions

Over decades of development and competition among shock manufacturers, damping curves have come a long way. Before we delve into the details of the different valving setups and their uses, let’s first talk about valve stacks and suspension tuning.

What components make up a proper stack? Generally speaking, your stack will consist of various shims in a multitude of diameters. The shims making up your stack will each carry out a different role in your stack’s construction. These shims include:

- Support shims

- Cover shims

- Bypass shims

- Bleed shims

- Preload shims

Your valve stack interacts with your shocks by controlling the pressure differentials created by the cycling of hydraulic fluid through your shock absorber. Shims on one stack will block oil flow through the piston, while the shims on the other stack allow oil to flow through. You can control the damping forces by increasing or decreasing the shims in each stack.

Related Read: How to Solve Handling Issues With A Shock Rebuild

Armed with this refresher course on valve stacks, let’s dive into your options for valving setups. Keep in mind that the setup that works like a dream on washboards won’t be the best fit for whoops. Your perfect damping curve will require you to make tradeoffs that ultimately result in the best performance for your vehicle, driving style, and events.

FREE DOWNLOAD - Damper Tuning Guide (Starter)

Ensuring a well-tuned damper setup can translate to significant performance gains on track. If you are unsure of where to begin the tuning process, this is a great starting point. Maximize the results of your shock adjustments with our free damper tuning guide download.

Linear Shock Valving

In the early days, most racing shocks had simple designs and damping curves. Linear damping curves were the norm at that time, but that doesn’t necessarily mean they’re entirely outdated.

Linear damping curves are designed like a spring curve: A linear rate controls the spring rate. The damping force increases at a constant rate as the velocity increases, giving us a linear damping curve.

Today’s popular use-cases for linear shock valving include streetcar applications, motorcycles, and even bicycles.

For other types of racing, you may still choose to use this damping style. A preference for linear shock valving depends on the driver’s feel, tire wear, race track surface, and the overall setup.

Progressive Shock Valving

At first glance, you might think a progressive-style damping curve looks most like a linear-style curve. However, delving into why this type of shock valve was developed, it’s easy to see that’s not the case.

As the name suggests, your setup starts out soft in a progressive setup and gets progressively stiffer as piston speed increases. This damping curve aims to have a higher rate of force gain in high-speed damping vs. low-speed damping. As a result, this damping curve is often associated with a smoother ride.

You can create this setup by modifying your shim stack or adding a bleed to the shock. This setup might be a good fit for you if you know you will encounter significant displacements or high velocities on your ride.

Some common applications for progressive shock valving are in off-road racing or riding environments. If you push on the rear of a dirt bike, you can feel it is very soft and moves freely, but when you hit a jump, the higher velocity is much stiffer damping.

Naturally, you would want a soft or compliant low-speed damping to allow the suspension to absorb bumps as easily as possible. Still, when you encounter larger bumps and displacements, you need to increase your damping, so your suspension doesn’t bottom out.

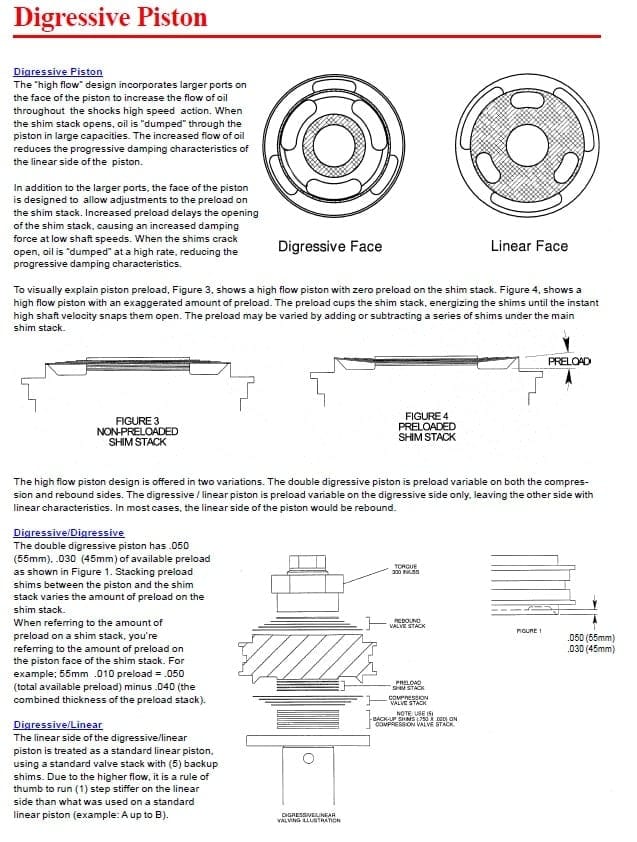

Digressive Shock Valving

Digressive shock valving first gained popularity in the United States in the mid-90s, though in series like F1, it showed up a bit earlier on the timeline.

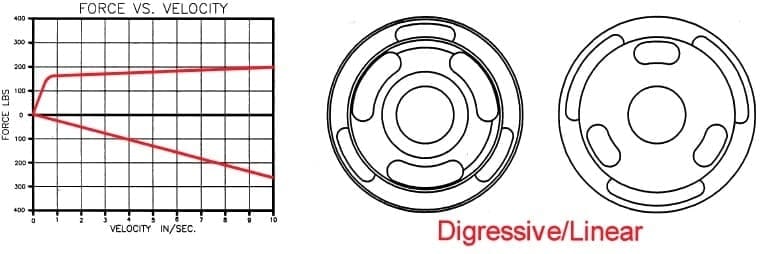

A digressive-style curve is exactly the opposite of a progressive setup. In this style, you start with a stiffer damping rate at a low speed that tapers off as the piston speed increases.

The draw of using this damping curve is that stiffer low-speed damping gives the driver a more stable feel, as low-speed damping is felt most strongly. When you’re using a linear curve, increasing the stiffness of low-speed damping creates even stiffer high-speed damping, which can cause trouble for large bumps or curbs.

This problem gave birth to the digressive-style curve, as it allows you to have a much stiffer rate of low-speed damping while avoiding that higher rate at high speeds. In other words, it allows you to enjoy the best of both worlds in this sense.

Some of the most common use-cases for digressive shock valving are in most forms of modern motorsports. Asphalt and dirt track racing for cars, motorcycles, and even bicycles have adopted digressive damping technology.

The digressive curve gave birth to other curve requests over the years.

The next two types of damping curves discussed in this post evolved directly from digressive shock valving.

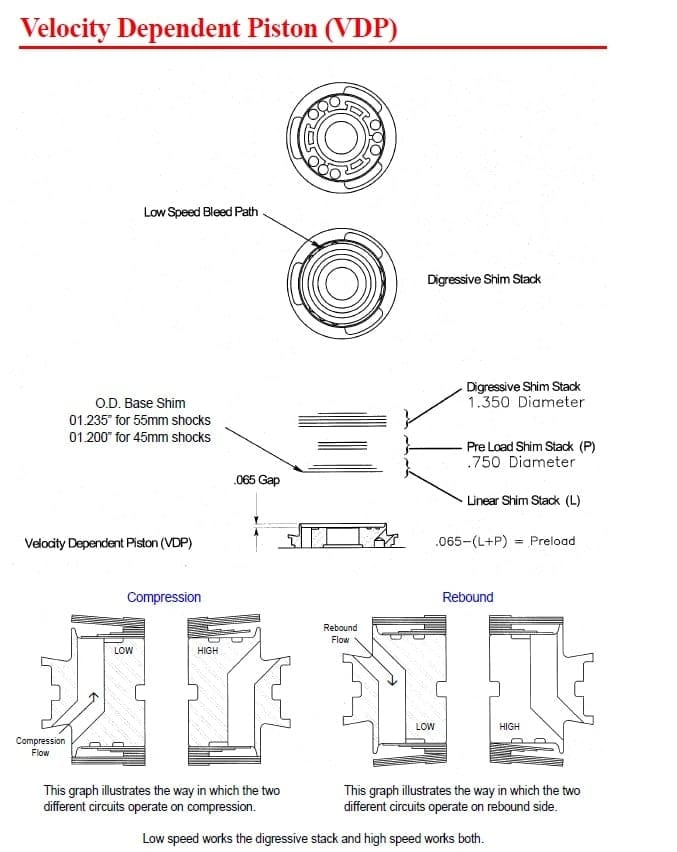

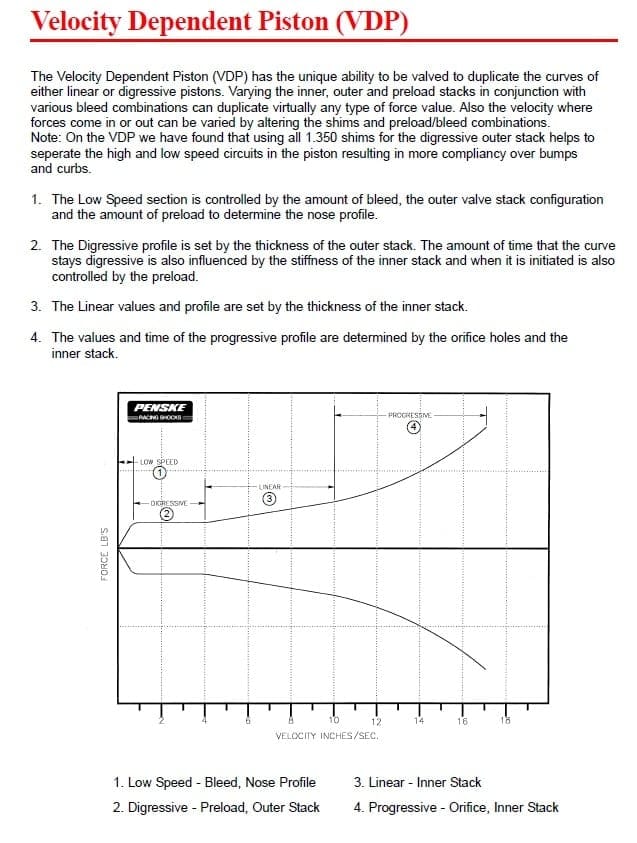

Velocity Dependent Piston

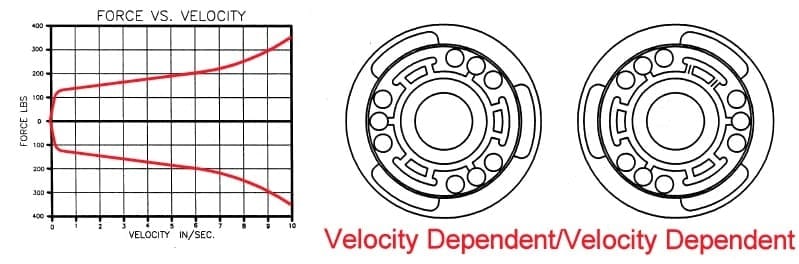

The Velocity Dependent Piston, most often called the VDP, was developed based on the digressive piston’s design.

Driver feedback on the original digressive piston design reported challenges with unexpected bumps in the road—literally. Imagine this scenario: You’re entering a corner, your suspension is loaded… and you hit a bump in that corner. To a driver, this can be a feeling of loss of support, stability, or overall grip.

The request born from this scenario was a desire to tune high-speed damping completely separately from low-speed damping. In this setup, the two shim stacks work independently of one another.

- The main shim stack that seals on the digressive lip is responsible for the low-speed “knee” digressive portion of the curve.

- The inner shim stack is designed to allow increased oil flow at a higher velocity to interact to allow the user to tune the high-speed portion of the damping curve.

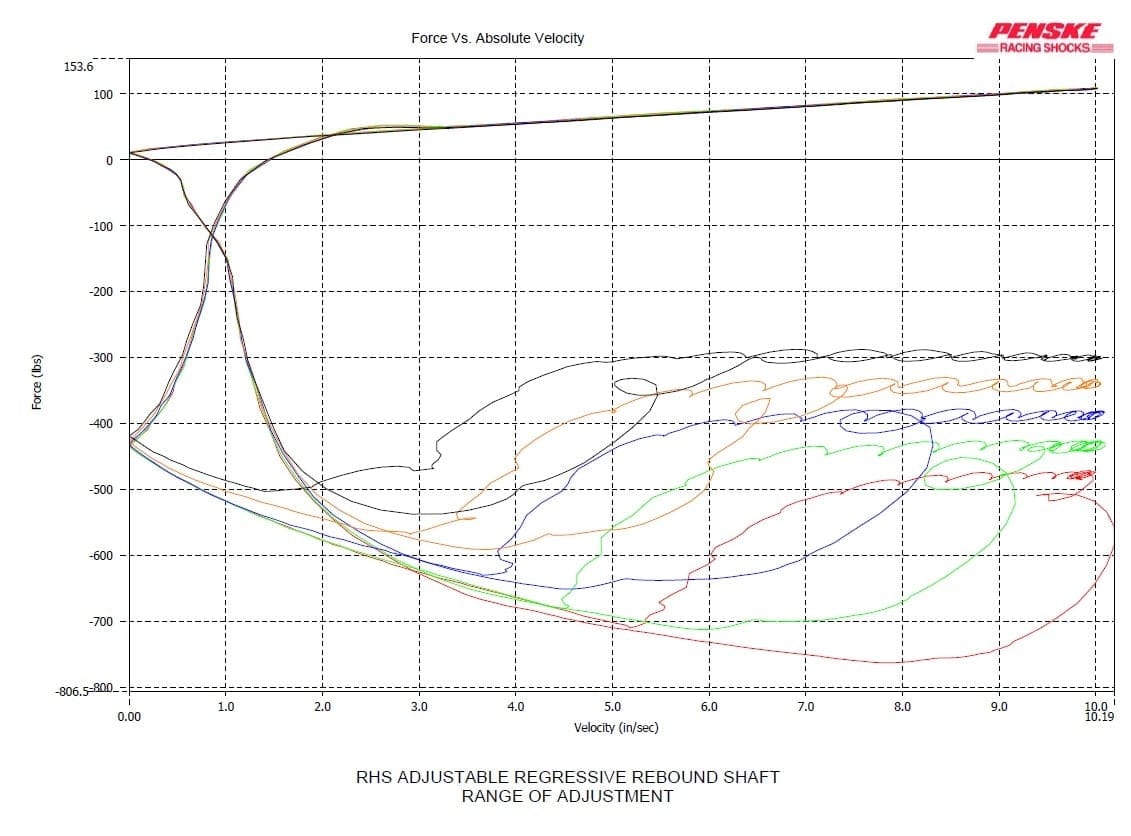

Regressive Shock Valving

Regressive shock valving is the latest development in shock valve technology. Essentially, a regressive-style curve is similar to the digressive style, simply taking the design to the next level.

The digressive damping curve came to be for two reasons:

- To increase low-speed damping to aid in support or platform

- To reduce high-speed force so as not to upset the chassis during large bumps

A regressive-style curve achieves this aim, becoming even softer at higher velocities than it is at low velocities. This type of control was long thought to be impossible—until the early 2000s.

In the 00s, an F1 customer determined that, though digressive-style curves were better than linear or progressive styles for curb strikes, a regressive-style curve would be even better. With this type of shock valving, a driver would be able to aggressively attack curbs and other large bumps without upsetting the chassis.

In the years since its development, racers have learned how to optimize the regressive damping style in the following ways:

- Approaching low-speed damping in increasingly aggressive ways, allowing the driver to get minimal spring rates, resulting in more mechanical grip.

- Approaching braking aggressively with rear rebound low-speed compression, resulting in stabler braking. (With other damping styles, this type of braking was impossible to achieve without damaging your tires or resulting in other handling issues.)

Digressive Shock Valving and More: How to Tune Any Shock Properly

Examining all the various setups for damping curves, you’ll see that there is truly no best-fit option for every scenario. All these shock valving styles have continued to develop and improve over the years, and each has its own use-cases, pros, and cons.

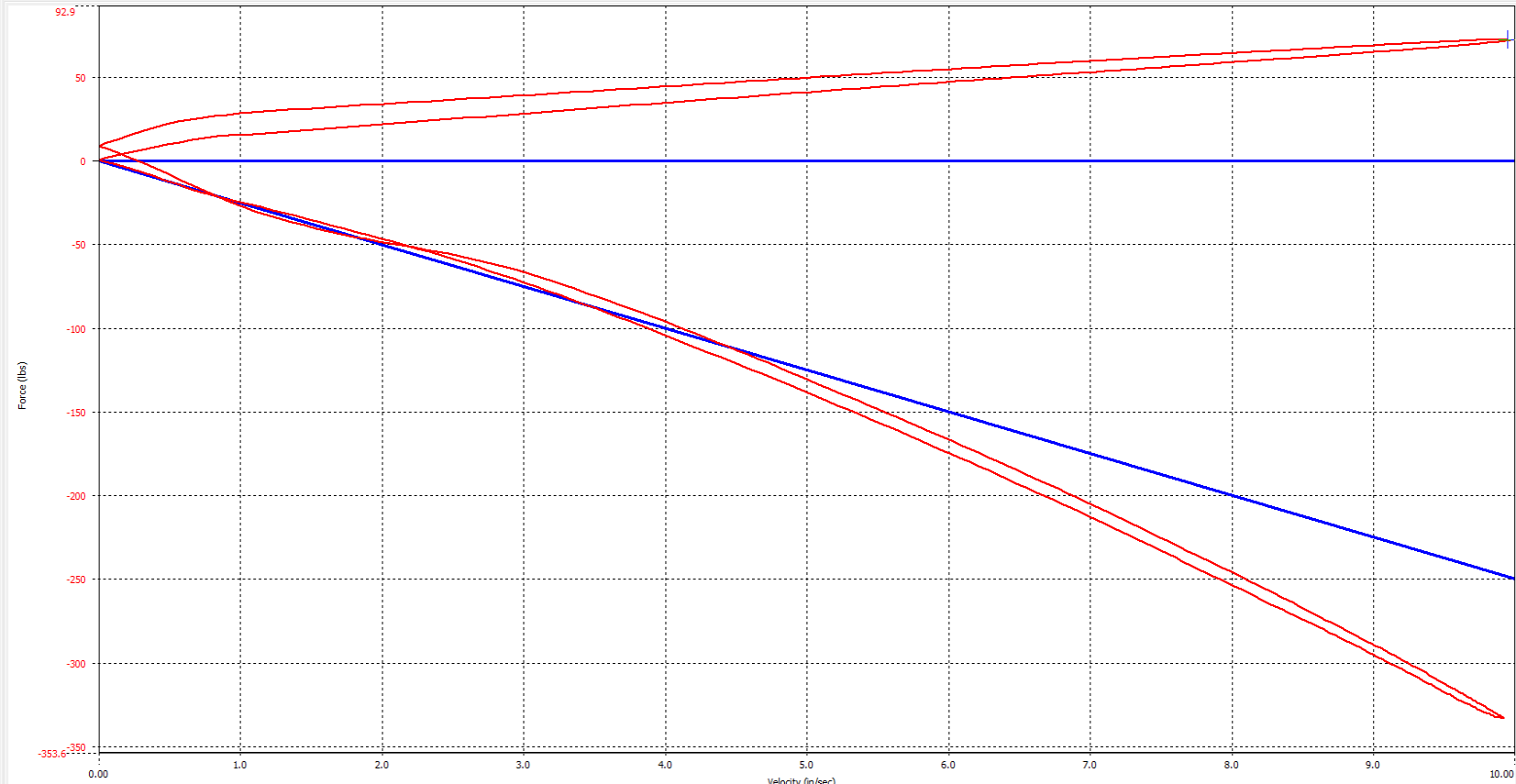

Regardless of your choice for your valving setup, you’ll need to keep your shocks tuned to maintain peak performance. Using a shock dyno is the only way to truly tune your shock to perfection. A shock dyno can also help you compare the different setup options, helping you make the right choice for your vehicle and race.

When you run each setup on a shock dyno, you’ll be able to see the exact numbers, helping you relate those changes to driver feel, tire wear, and other handling characteristics.

For support, guidance, and setup assistance with your shock valving, no matter your setup, explore Penske Racing Shocks S3 program today. With S3, you’ll have access to the right hardware for your application, a personalized shock setup, and the backend support you need.

%20(1).png?width=1080&height=1080&name=Heritage%20Cruiser%20Shock%20-%20IG%20(1)%20(1).png)