Monotube vs. Twin-Tube Shocks: Which is Best for Performance

September 6, 2021

Would you prefer water or an energy drink?

Ultimately, your decision depends on your goal. They're both drinks, but they each have a distinct purpose.

The decision of monotube vs. twin-tube shocks is similar. Both provide suspension, but they each have a distinct purpose.

While many people have opinions (even with the "water or energy drink" question), each suspension type can give you a marked advantage in specific scenarios.

We've compiled a list of the variables often considered when purchasing suspension and the differences between monotube and twin-tube shocks. This list should make it easy to see which shock is best for you.

Which is Best for Your Performance: Monotube or Twin-Tube Shocks?

The critical element in determining which shock type is best for you comes down to the vehicle you drive and how you drive it. Driving or riding something that doesn't feel right will hurt your ultimate performance.

What is a monotube shock?

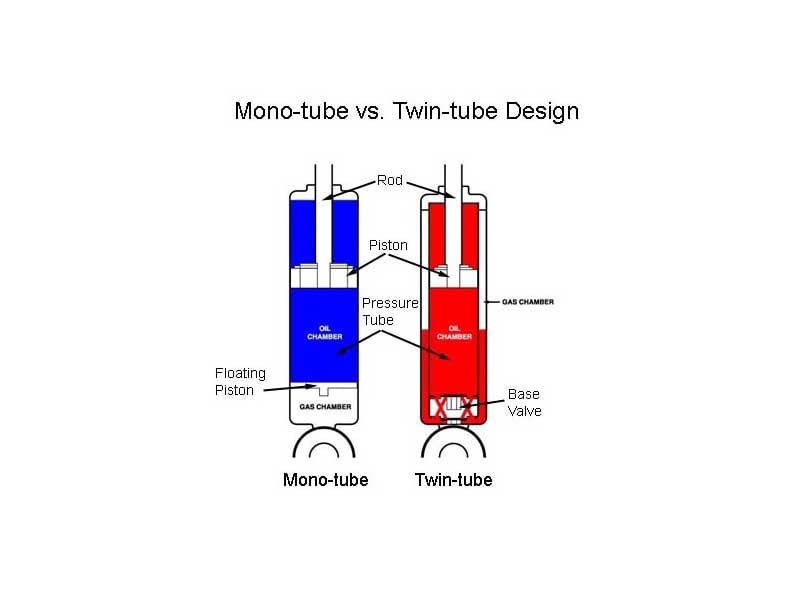

In a monotube shock, the shell case itself works as a cylinder, carrying oil, gas, and a piston valve. It's a single tube, and a floating piston separates the oil chamber from the gas chamber. They're used in most race cars because they provide a stiffer ride, and their damping forces are more precise, giving the driver more control.

What is a twin-tube shock?

In a twin-tube shock, there are two cylinders. One cylinder sits inside a shell case. The interior cylinder contains the piston valve. There is no piston or barrier between the oil and gas chambers. The main advantage of a twin-tube design is the packaging.

Monotube vs. Twin-Tube Shocks

Both monotube and twin-tube shocks perform similar jobs; to make your ride more comfortable and give you the edge when it comes to car handling and suspension performance.

Still, there are a few key differences to consider, like how they're built.

Learn more about The Advantages (and Disadvantages) of Monotube Shocks.

Shock Installation

Because of their design, most twin-tube shocks can only be installed in one position; if installed upside down, the shock will not perform. Monotube shocks have a separator piston that keeps the gas separate from the oil. So the shocks can be installed right-side up, upside down, or even laying flat like on a formula car.

Shock Design

In a monotube shock, the oil and gas chambers are entirely separated by a floating piston. There is no aeration or foaming, and the valving becomes much more responsive. Higher gas pressure offers additional resistance, giving the monotube variable for tunability. Increased performance just when you need it!

Because the gas itself becomes part of the spring action, it compresses over smaller bumps and quicker through bigger hits, which improves control and response.

Monotubes have a larger surface area to spread the load, distributing pressure evenly over the entire shock and typically resulting in a more efficient and better performance.

In twin-tube shocks, either air or nitrogen is inserted at low pressure into the outer tube above the valve to prevent it from escaping into the inner tube. This keeps pressure on that end of the oil, minimizing aeration or foaming - that occurs when the shocks are under hard use (this will be important later).

Shock Cost

There are differences in cost between the two applications.

Twin-tube designs are generally used in OE applications for their higher stroke vs. overall length compared to monotube designs. Typically a twin-tube is a cheaper shock simply because they are mass-produced.

Monotube-designed shocks are typically hand-built with performance in mind, making them more expensive but custom for a specific application.

Shock Maintenance

Shocks suffer the same effect as any hydraulic circuit having air mixed inside - which can lead to poor damping when air mixes with fluid, which happens more easily in the twin-tube design. This isn't ideal for high performance.

Fading is also an issue. Constant pressure on the shock may lead to the performance of the shock fading (which happens with foaming in twin-tubes); hence the damping becomes weaker, causing handling issues or changes.

Monotubes are typically the shock design of choice for racers. They are easier to work on, allowing for easier maintenance or performance changes.

Check out our ON-DEMAND WEBINAR: Top 10 Most Common Suspension Issues & How to Resolve Them

Monotube vs. Twin-Tube: What Does This Mean For You

If all you're after is a shock to control your spring and give you a somewhat comfortable ride, while not costing you too much, twin-tubes are the best bang for your buck.

When it comes to performance, custom feel, and all-out repeatability and reliability, monotube shocks are superior because:

- Better damping force

- Better heat dissipation

- The free-floating piston stop the gas and oil from mixing

- Better changes from smooth to stiff suspension

- Ease of installation

- Higher performance

Purchasing Your Monotube Shocks

So there you have it. If you're in a streetcar looking for comfort, the more cost-effective solution is a twin-tube design. But for performance, it has to be a monotube, as the benefits far outweigh the initial investment.

If you want to discuss monotube shocks more, speak to one of the shock specialists at Penske Racing Shocks. Rather than buying a set of shocks that are configured to work for everyone, you will work directly with the Penske Shocks team to begin the setup optimization process BEFORE purchasing anything. Customizing the hardware selection and setup process to your specific application and your particular needs ensures you get more out of your shock setup faster.

After you purchase your shocks and customize your setup, you'll receive continued support from the Penske team. To learn more about our S3 process (Shocks + Setup + Support), reach out to us here and get the ball rolling.